產品詳情

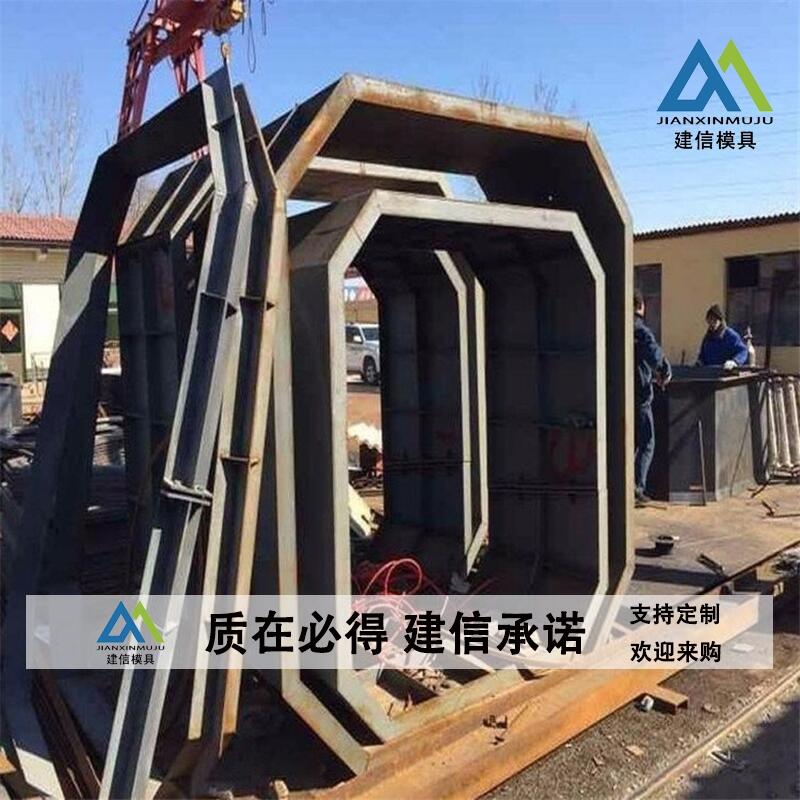

觀察井模具制作原理與說明來說應用于各種工程中,用來制作不同大小的檢查井預制件,在使用的時候則是按照預制的方式進行操作,這些預制的加工步驟簡單,容易上手進行操作,而且也可以制作出大量合格的預制件,那么在進行處理的時候,則需要注意好對于模具的一些生產環節的掌控。比如說在組裝的時候使用的螺栓零件,必須保證螺栓螺紋清晰,不可以出現磨損過度或者是螺紋之間有大量油污情況的出現。因為螺栓是用來進行模具組裝的,如果螺栓規格達不到使用的標準,那么觀察井模具在進行生產時就容易出現拼接組裝不穩定的問題,或者是泥漿無法正常凝固,出現泥漿泄露的情況。所以說在進行處理的時候一定要注意好對于整個觀察井模具的保護,當然也要對于模具來進行一些合理的養護處理。組裝后的模具中則是需要進行刷油的,一般都是需要刷上脫模劑來減少泥漿與模具的粘連,也是為了加快脫模的時間,刷上油的模具才可以正常來進行泥漿的澆筑。

According to the manufacturing principle and debion of the observation well mold, it is used in various projects to make prefabricated parts of inspection wells of different sizes. When it is used, it is operated according to the prefabrication b. These prefabrication processing steps are simple and easy to operate, and a large number of qualified prefabricated parts can also be made. Then when processing, You need to pay attention to the control of some production bs of the mold. For example, the bolt parts used during assembly must ensure that the bolt threads are b, and there can be no excessive wear or a large amount of oil contamination between the threads. Because the bolt is used for mold assembly, if the bolt specification does not meet the use standard, the observation well mold is prone to unstable splicing and assembly during production, or the mud cannot solidify normally, resulting in mud leakage. Therefore, during treatment, we must pay attention to the protection of the whole observation well mold, and of course, we should also carry out some reasonable maintenance treatment for the mold. The assembled molds need to be painted with release agent to reduce the adhesion between mud and molds. In order to speed up the demoulding time, the painted molds can be poured with mud normally.

According to the manufacturing principle and debion of the observation well mold, it is used in various projects to make prefabricated parts of inspection wells of different sizes. When it is used, it is operated according to the prefabrication b. These prefabrication processing steps are simple and easy to operate, and a large number of qualified prefabricated parts can also be made. Then when processing, You need to pay attention to the control of some production bs of the mold. For example, the bolt parts used during assembly must ensure that the bolt threads are b, and there can be no excessive wear or a large amount of oil contamination between the threads. Because the bolt is used for mold assembly, if the bolt specification does not meet the use standard, the observation well mold is prone to unstable splicing and assembly during production, or the mud cannot solidify normally, resulting in mud leakage. Therefore, during treatment, we must pay attention to the protection of the whole observation well mold, and of course, we should also carry out some reasonable maintenance treatment for the mold. The assembled molds need to be painted with release agent to reduce the adhesion between mud and molds. In order to speed up the demoulding time, the painted molds can be poured with mud normally.

According to the manufacturing principle and debion of the observation well mold, it is used in various projects to make prefabricated parts of inspection wells of different sizes. When it is used, it is operated according to the prefabrication b. These prefabrication processing steps are simple and easy to operate, and a large number of qualified prefabricated parts can also be made. Then when processing, You need to pay attention to the control of some production bs of the mold. For example, the bolt parts used during assembly must ensure that the bolt threads are b, and there can be no excessive wear or a large amount of oil contamination between the threads. Because the bolt is used for mold assembly, if the bolt specification does not meet the use standard, the observation well mold is prone to unstable splicing and assembly during production, or the mud cannot solidify normally, resulting in mud leakage. Therefore, during treatment, we must pay attention to the protection of the whole observation well mold, and of course, we should also carry out some reasonable maintenance treatment for the mold. The assembled molds need to be painted with release agent to reduce the adhesion between mud and molds. In order to speed up the demoulding time, the painted molds can be poured with mud normally.